Surface hardening and functional coating layer are applied for roll in medium and low temperature section of furnace ,on line roll (bridle roll, deflector roll, steering roll, pinch roll etc.), and sink roll, stable roll in zinc pot for CGL and CAL, so that life time is effectively extended for various kinds of roll, strong guarantee is given for stable running of production line. This technology has been successfully widely applied in Baosteel, Shougang, Masteel, Bengang, Ansteel, Tangsteel, Baogang,Tagal and overseas steel plants.

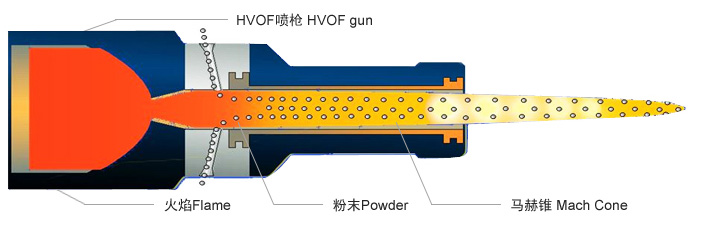

High velocity of flame spray (abbreviated as HVOF) is a kind of technology which is to mix fuel (Hydrogen, propane, propylene and aviation kerosene) with high pressure oxygen in mixing chamber and violently combusted to generate stable high speed and high pressure flame flow, when it passes through a special designed larval nozzle, and speeded up to be supersonic flame flow, powder is sent into flame and heated and speeded up, particle is shot in melt or semi-melt form to the surface of base of part to become coating layer . By means of selection of best coating material and optimized spraying process, it can make cermet in Cr3C2 series which is high temperature oxidation resistance, wearing and anti-corrosion coating layer, as well, WC series cermet which is anti-wearing and corrosion coating; we can also provide anti-melt cermet for part elements, like sink roll in zinc pot, special cermet for anti-wearing coating layer.